- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

PRODUK

Accelerator CBS(CZ)-80

Fitur Produk:

Komposisi:

80% N-cyclohexyl-2-benzothiazolylsulfenamide, 20% rubber carrier and processing aids

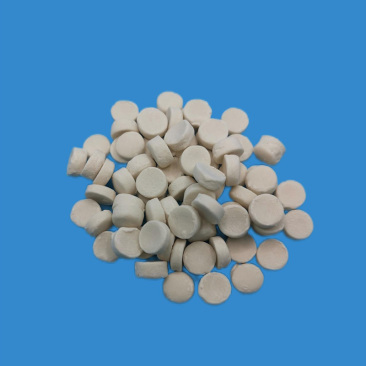

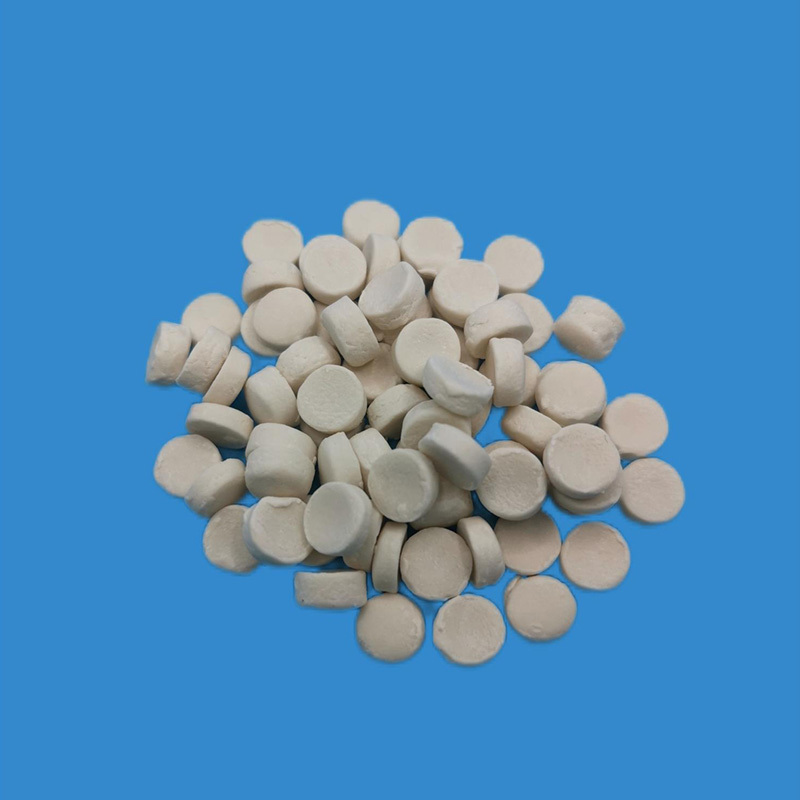

Appearance:

Gray-white particles

Kepadatan:

Sekitar. 1.3 g/cm3

Dosis:

Jumlah penggunaan klasik adalah 0.5~2.0, dan jumlahnya dapat ditambah atau dikurangi sesuai dengan efeknya.

Kemasan:

25 kg/kemasan

Stabilitas penyimpanan:

12 bulan dalam kondisi penyimpanan normal

Penanganan:

Silakan lihat informasi keselamatan produk MSDS

Fitur Teknis

Akselerator CBS adalah akselerator tunda untuk karet alam dan karet sintetis, yang memiliki dua keunggulan ketahanan gosong yang sangat baik dan kecepatan vulkanisasi yang cepat. Sangat aman selama pengoperasian. Dalam vulkanisasi sulfur rendah dapat digunakan sendiri, juga dapat digunakan dengan akselerator dithiocarbamate atau thiuram, vulkanisat yang dihasilkan memiliki ketahanan penuaan yang baik dan ketahanan deformasi permanen kompresi. Waktu gosong senyawa tersebut dipersingkat secara signifikan setelah CBS dan akselerator dithiocarbamate dan akselerator thiuram digunakan. Akselerator thiourea memiliki efek promosi sekunder yang signifikan pada CBS, terutama pada senyawa sulfur rendah. Dalam senyawa yang mengandung akselerator alkohol sulfur dan akselerator thiuram, CBS dapat menunda gosong dan meningkatkan keamanan pemrosesan. Pada suhu pengawetan (di atas 138 ℃), efek promosi sangat kuat, terutama cocok untuk senyawa karbon hitam tungku minyak yang mengandung alkali tinggi. Produk ini tidak menyemprotkan embun beku, mudah tersebar dalam karet, karet vulkanisasi memiliki sifat mekanik yang sangat baik dan ketahanan penuaan. NR: Akselerator utama: 0,5-1,0 bagian dan 2,5-3,5 bagian sulfur. SBR: 1,0-1,5 bagian dan 0,1-0,5 bagian akselerator jenis thiuram yang dikombinasikan dengan 1,5-2,5 bagian sulfur.

Aplikasi

Terutama digunakan dalam pembuatan ban, ban dalam, selang, pita, sepatu karet, kabel, ban, produk industri, dll.