- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

PRODUK

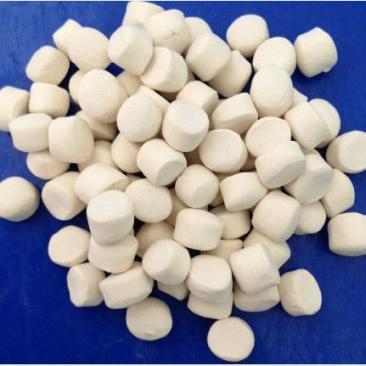

Accelerator MBTS(DM)-75

Fitur Produk:

Komposisi:

75% dibenzothiazole disulfide, 25% rubber carrier and surfactant

Tampilan:

Light Partikel Kuning

Kepadatan:

Sekitar. 1.3 g/cm3

Dosis:

Jumlah penggunaan klasik adalah 0.1~2.0, dan jumlahnya dapat ditambah atau dikurangi sesuai dengan efeknya.

Kemasan:

25 kg/kemasan

Stabilitas penyimpanan:

12 bulan dalam kondisi penyimpanan normal

Penanganan:

Silakan lihat informasi keselamatan produk MSDS

Fitur Teknis

MBTS adalah karet alam dan berbagai akselerator karet sintetis, dengan keamanan pemrosesan yang baik dari akselerator kuasi-kecepatan berlebih universal, dapat digunakan sendiri juga dapat digunakan dengan akselerator lain. Dapat menghasilkan fluidisasi kecepatan datar dan sedang, suhu vulkanisasi lebih tinggi, ada efek samping yang signifikan, bukan vulkanisasi awal, operasi yang aman, dispersi mudah, tidak ada polusi. Kecepatan vulkanisasi produk ini sendiri lambat, biasanya dengan thiuram, dithiocarbamate, amina aldehida, akselerator guanidin dan penggunaan. Ini memiliki efek penundaan dalam pemrosesan dan vulkanisasi senyawa CR tipe-G, dan memiliki ketahanan hangus yang sangat baik. Ketika digunakan dalam kombinasi dengan akselerator kecepatan berlebih, MBTS dapat meningkatkan keamanan proses. Vulkanisat MBTS memiliki ketahanan penuaan panas yang baik. Akselerator utama NR dan SBR: 1,0-2,0 bagian MBTS dan 2,0-3,0 bagian sulfur dikombinasikan dengan akselerator IIR: 0,25-1,0 bagian MBTS dan 1,0-2,0 bagian sulfur dikombinasikan.

Aplikasi

Terutama digunakan dalam pembuatan ban, selang, sepatu karet, karet keras, pita dan produk industri karet lainnya.