- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

PRODUK

Accelerator TBBS(NS)-75

Fitur Produk:

Komposisi:

80% N-tert-butyl-2-benzothiazolylsulfenamide, 20% Rubber Carrier * and Processing Aids

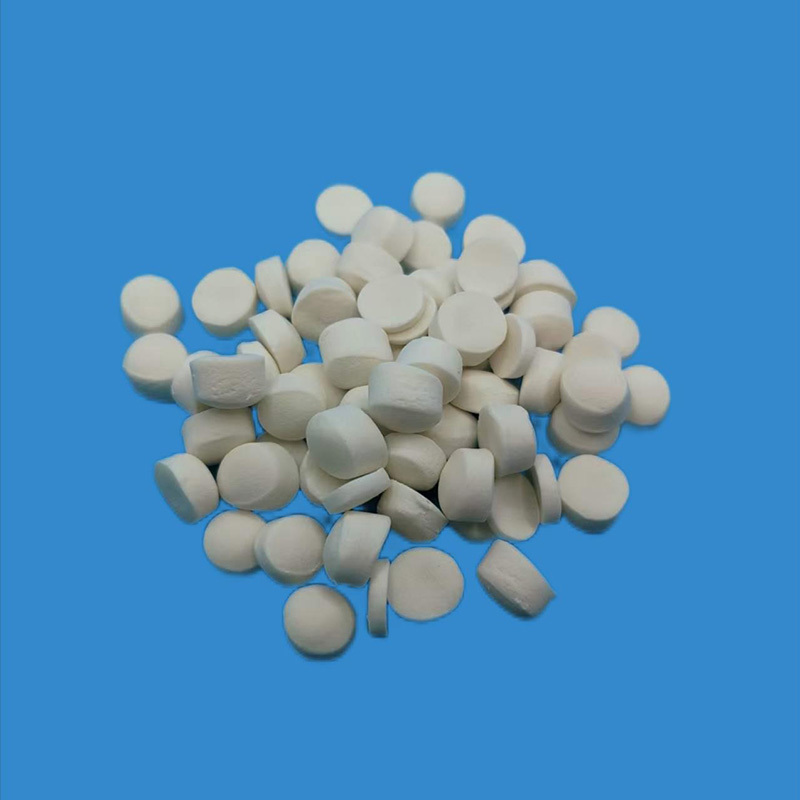

Tampilan:

Partikel putih

Kepadatan:

Sekitar. 1.2 g/cm3

Dosis:

Jumlah penggunaan klasik adalah 0.5~2.0, dan jumlahnya dapat ditambah atau dikurangi sesuai dengan efeknya.

Kemasan:

25 kg/kemasan

Stabilitas penyimpanan:

12 bulan dalam kondisi penyimpanan normal

Penanganan:

Silakan lihat informasi keselamatan produk MSDS

Fitur Teknis

TBBS adalah karet alam, karet butadiena, karet isoprena, karet stirena butadiena dan akselerator efek samping karet reklamasi, terutama cocok untuk karet karbon hitam yang mengandung alkali kuat. Aman pada suhu operasi, ketahanan hangus yang kuat, kecepatan pengeringan cepat, kekuatan tarik tinggi. Dalam vulkanisasi sulfur rendah dapat digunakan sendiri, juga dapat digunakan dengan akselerator dithiocarbamate atau thiuram, vulkanisat yang dihasilkan memiliki ketahanan penuaan dan modulus yang baik. Toksisitas rendah dan efisiensi tinggi, adalah pengganti yang ideal untuk NOBS, memiliki kinerja komprehensif yang sangat baik, disebut akselerator standar. Banyak digunakan dalam produksi ban radial. Dapat digunakan dengan akselerator aldehida amina, guanidin dan thiuram, dan ketika digunakan dengan agen anti-hangus PVI, itu merupakan sistem vulkanisasi yang baik. Terutama digunakan untuk ban, sepatu karet, selang, pita, pembuatan kabel. NR: 0,5-1,0 bagian TBBS dan 2,5-3,5 bagian sulfur; SBR: 1,0-1,5 bagian TBBS, 0,2 bagian akselerator thiuram dan 1,5-2,5 bagian sulfur.

Aplikasi

Terutama digunakan untuk pembuatan ban, sepatu karet, selang, pita, kabel.

ID

ID EN

EN