PRODUCTS

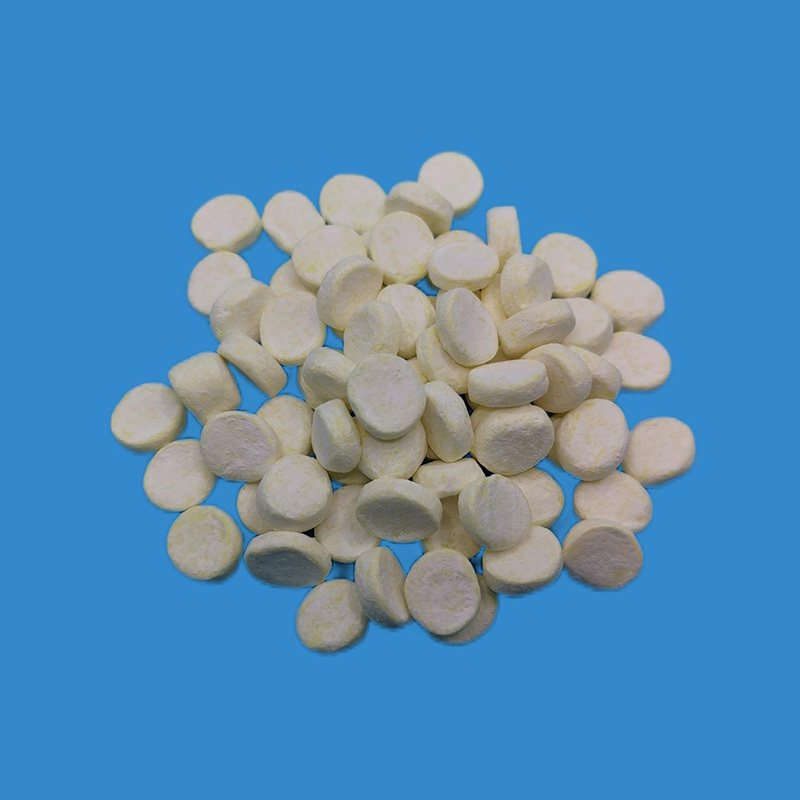

Accelerator TMTM(TS)-75

Product features:

Composition:

75% tetramethylqiuram monosulfide, 25% rubber elastomeric carrier and surfactant

Appearance:

Yellow particles

Density:

Approx. 1.2 g/cm3

Dosage:

The classic usage amount is 0.1~3.0, and the amount can be increased or decreased according to the effect.

Packing:

25 kg/package

Storage stability:

12 months under normal storage conditions

Handling:

Please refer to the product safety information MSDS

Technical features

The accelerator TMTM is a super accelerator that does not change color and does not pollute. When used in natural rubber and synthetic rubber, the vulcanization speed is very fast and the scorch safety is good. The activity is about 10% lower than that of the accelerator TMTM, and the tensile strength of the vulcanizate is also slightly lower. The critical temperature of vulcanization is 121 ℃, the post-vulcanization effect is greater than that of thiuram disulfide and dithiocarbamate accelerators, and the scorch resistance is excellent. The accelerator TMTM can be used alone or in combination with an accelerator such as thiazoles, aldehyde amines, and guanidines, and is an active agent of the thiazole accelerator. In general-purpose (GN-A type) butyl rubber has the effect of delayed vulcanization. When combined with dithiocarbamate in latex, the tendency of the compound to vulcanize early is reduced. Accelerator TMTM can not be decomposed into active sulfur, can not be used for sulfur-free coordination.

Application

The accelerator TMTM is a super accelerator that does not change color and does not pollute. When used in natural rubber and synthetic rubber, the vulcanization speed is very fast and the scorch safety is good.

Id

Id  En

En