- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

PRODUK

Accelerator TBzTD-75

Fitur Produk:

Komposisi:

75% tetrabenzyl thiuram disulfide, 25% EPDM rubber carrier

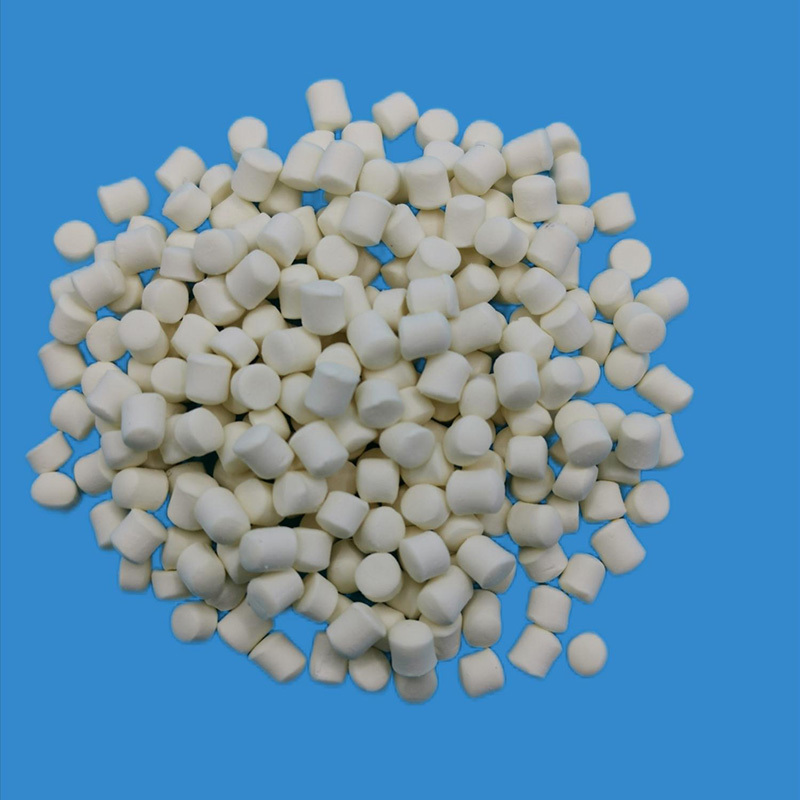

Appearance:

Light Partikel Kuning

Kepadatan:

Sekitar. 1.2 g/cm3

Dosis:

Jumlah penggunaan klasik adalah 0.5~2.0, dan jumlahnya dapat ditambah atau dikurangi sesuai dengan efeknya.

Kemasan:

25 kg/kemasan

Stabilitas penyimpanan:

12 bulan dalam kondisi penyimpanan normal

Penanganan:

Silakan lihat informasi keselamatan produk MSDS

Fitur Teknis

TBzTD adalah akselerator ramah lingkungan yang tidak melepaskan senyawa nitrosamin karsinogenik selama proses vulkanisasi. Bila digunakan sebagai akselerator vulkanisasi untuk karet alam dan karet sintetis, ia memiliki karakteristik keamanan pemrosesan yang tinggi dan kecepatan vulkanisasi yang cepat. Penambahan akselerator tiazol atau sulfenamida akan memperlambat proses vulkanisasi, waktu hangus dan vulkanisasi akan dipersingkat, dan tingkat vulkanisasi tidak akan meningkat secara signifikan. Akselerator dasar seperti amina aldehida dan guanidina memiliki tindakan pengaktifan. TBzTD biasanya digunakan untuk vulkanisat bebas sulfur atau rendah sulfur dengan ketahanan panas yang sangat tinggi.

Aplikasi

Untuk sistem NR, SBR, EPDM, NBR dapat digunakan sebagai akselerator primer atau akselerator sekunder yang cepat. Umumnya digunakan pada tapak ban, selang, sabuk konveyor, alas kaki karet, dan produk industri lainnya.