- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

PRODUK

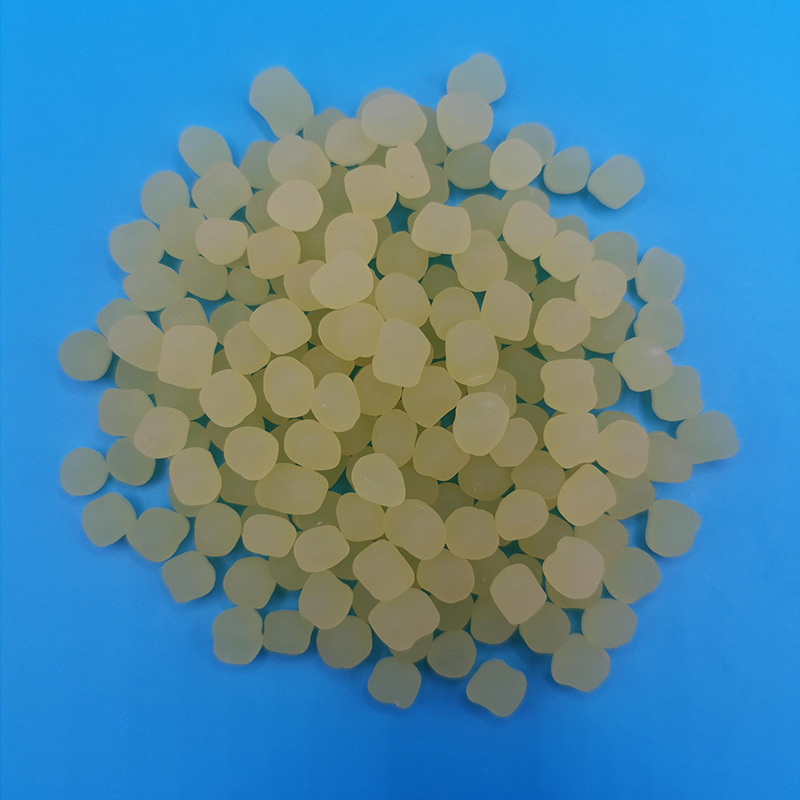

Coupling agent SI-50

Fitur Produk:

Komposisi:

50% bis-(γ-triethoxysilylpropyl) tetrasulfide, 50% rubber-elastic carrier and surfactant

Tampilan:

Partikel Kuning

Kepadatan:

Sekitar. 1.2 g/cm3

Dosis:

Jumlah penggunaan klasik adalah 2.0~8.0 parts, dan jumlahnya dapat ditambah atau dikurangi sesuai dengan efeknya.

Kemasan:

20 kg/piece

Stabilitas penyimpanan:

12 bulan dalam kondisi penyimpanan normal

Penanganan:

Silakan lihat informasi keselamatan produk MSDS

Fitur Teknis

Si-50 adalah masterbatch agen penggandeng yang berhasil diaplikasikan pada karet. Ia memiliki dispersi dan kompatibilitas yang lebih tinggi dengan karet, dan ramah bagi operator dan lingkungan. Tidak ada kehilangan material selama pengoperasian dan tidak ada kebocoran debu dan cairan, sehingga efisiensi pencampuran dapat ditingkatkan dan konsumsi energi dapat dikurangi. Kegunaan utama: 1. Aditif karet multifungsi, cocok untuk persyaratan khusus produk karet berkinerja tinggi yang tidak berwarna atau berwarna terang, meningkatkan kemampuan penguatan pengisi, merupakan bagian penting dari sistem vulkanisasi untuk meningkatkan kinerja ikatan silang, karbon hitam dan karbon hitam putih dan pengisi lainnya dan karet dikombinasikan dengan baik untuk meningkatkan modulus dan ketahanan aus produk. 2. Vulkanisasi seimbang, empat atom sulfur dalam molekulnya dan sulfur berpartisipasi dalam reaksi ikatan silang polisulfur, dan kecepatan ikatan silang gugus tetrasulfanil kira-kira sama dengan kecepatan pembalikan sulfur dalam vulkanisasi sulfur, sehingga dapat menahan pembalikan dan membentuk senyawa anti-pembalikan yang sesuai. Sifat lentur dinamisnya (seperti pembangkitan panas, pemanjangan retak, dll.) telah ditingkatkan secara signifikan. 3. Efek vulkanisasi dan peningkatan aktivitas, efek peningkatan atau perubahan penuaan pada perangkat vulkanisasi.

Aplikasi

Produk ini banyak digunakan pada: ban, sol karet, rol karet, pita dan produk karet lainnya, dapat meningkatkan ketahanan aus produk, kekuatan tarik, kekuatan sobek, meningkatkan penuaan termal, meningkatkan pembengkokan, tetapi juga dapat meningkatkan kinerja pemrosesan pencampuran, kinerja denaturasi sulfur, mengurangi konsumsi energi.